SALES AND RENTALS

Kitchen’s Crane & Equipment partners with Enerpac to bring you the best in heavy lifting equipment. Enerpac combines high pressure hydraulics and controls to deliver intelligent and innovative solutions that maintain the highest level of quality, reliability and safety.

Contact us to learn more about available units today! info@kitchensequipment.com

Hydraulic gantries are a safe, efficient way to lift and position heavy loads in applications where traditional cranes will not fit and permanent overhead structures for job cranes are not an option. When used with rail systems, hydraulic gantries also provide a means for moving and placing heavy loads. Hydraulic gantries are a cost effective solution for many lifting and rigging applications.

The strand jack lifting technique originates from the concrete post tensioning principle. A strand jack can be considered a linear winch. In a strand jack, a bundle of steel cables or strands are guided through a hydraulic cylinder; above and below the cylinder are anchor systems with wedges that grip the strand bundle. By stroking the cylinder in and out while the grips are engaged in the anchors, a lifting or lowering movement is achieved.

Improve the safety and speed of your next lift with the Self-Locking Cube Jack. `0======] new 100-ton SCJ-100 model is an addition to the previously released 50-ton SCJ-50 Cube Jack. Self-Locking Cube Jacks are a compact and portable hydraulic solution for incremental lifting and lowering of heavy loads. The Cube Jack uses a base lifting frame and self-aligning, lightweight steel cribbing blocks to provide high-capacity and stabilized lifting.

The Jack-Up System is a multipoint lifting system. A typical system setup includes four jack-up units positioned under each corner of a load. A four-unit setup has a lifting capacity of 2,000 metric tons (500 tons per unit). The lifting frame of a jack-up contains four hydraulic cylinders in each corner which lift and stack steel boxes. A load is lifted in increments as boxes are slid into the system, lifted, and stacked; forming ‘lifting towers’. A Jack-Up System is operated and controlled by a computer control unit. Each unit’s lifting and lowering operations occur simultaneously; the computer control unit’s synchronous technology maintains the load’s balance. The hydraulic power units are embedded within each unit’s lifting frame. Safe lifting heights are dependent on the expected side load.

For lifting and lowering applications with multiple points, controlled lifting pumps are a far better alternative than using independently operated pumps. To achieve high-precision movement of heavy objects it is necessary to control and synchronize the movements of multiple lifting points. By controlling the oil flow to each cylinder, the pumps maintain very accurate positional control. By eliminating manual intervention, controlled lifting pumps help maintain structural integrity and increases the productivity and safety of a lift.

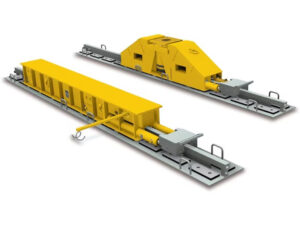

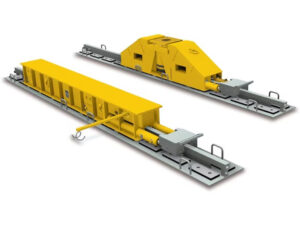

Enerpac has applied high-pressure hydraulics to maximize the efficiency of our skidding systems. A skidding system is comprised of a series of skid beams moved by hydraulic push-pull cylinders, traveling over a pre-constructed track. A series of special PTFE-coated pads are placed on the skid tracks to reduce friction. The push pull cylinders are then connected by hoses to a pump.

Turntables for safe and controlled rotation of heavy loads. The ETT-Series Turntable is your solution for rotating heavy loads during, before or after a lifting and skidding operation.